Press Release

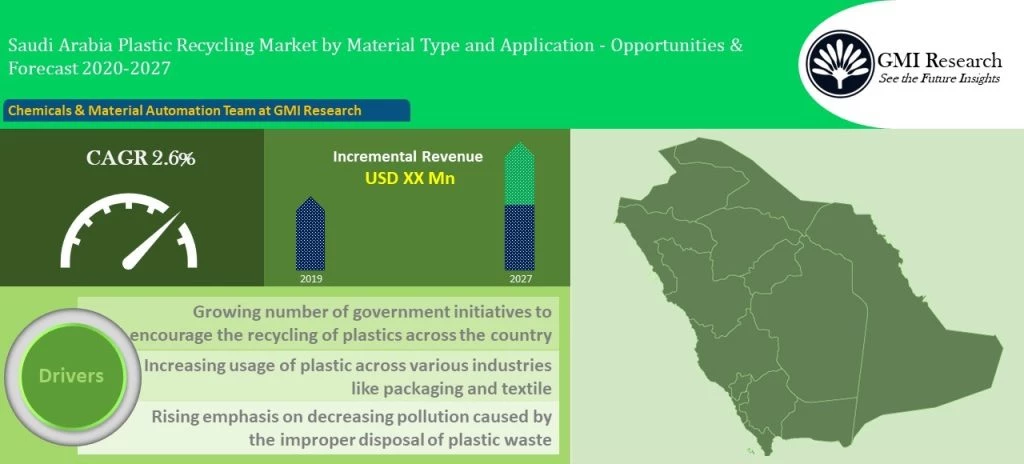

As per the GMI Research forecasts, the rise in the number of government initiatives to support the recycling of plastics in the country is one of the biggest factors that is responsible for the growth of the market. The Saudi Arabia Plastic Recycling market was estimated to be USD XX Million in 2019 and is predicted to reach USD XX Million by the end of 2027, while growing at a CAGR of 2.6% during the forecast period (2020-2027).

Saudi Arabia Plastic Recycling market is expected to witness an upsurge in demand over the forecast period. The rise in the number of government initiatives to support the recycling of plastics in the country is a significant factor that is contributing to the growth of the market. Moreover, the growing utilization of plastics in numerous sectors including food & beverages, textile, packaging, and other sectors is further surging the growth of the market. In addition to this, the growing focus on infrastructural development, such as the construction of smart cities and expansion in the food & beverage sector, are some other factors that are attracting new consumer base towards the market.

Several companies are focusing on introducing innovative packaging solutions to cater to the changing demand of the market. For instance, SABIC, a chemical manufacturing company, launched a new sustainable packaging solution that comprises polyethylene grade & advanced film production technology for frozen food packaging applications. Furthermore, the Saudi Arabian government is aiming to increase the plastic recycling activities in the country. The Board of Directors of the Saudi Standards, Metrology and Quality Organization (SASO) approved the formation of a working group with the representatives of the Ministry of Environment, Water, Agriculture. This community will help in increasing the recycling activities in Saudi Arabia in accordance with modern technologies, best international practices, and mechanisms.

To have an edge over the competition by knowing the market dynamics and current trends of “Saudi Arabia Plastic Recycling Market,” request for Sample Report here

The growing level of pollution caused by the dumping of used plastics in water bodies and the shortage in the landfill areas are encouraging the recycling of plastics in order to decrease the pollution. The constant technological advancement in plastic recycling technologies is another factor that is creating new growth opportunities for the market growth. In 2020, SABIC launched a sustainable packaging solution by using mono web TF-BOPE film for frozen food applications. This 100% recyclable film is made with the help of Ticinoplast and Plastchim-T film suppliers and the packaging machine manufacturer Syntegon Technology. It also offers various advantages such as high yield, better printability, cost-saving opportunities, and decreased consumption of plastic materials. On the other edge of the spectrum, the lack of proper adequate infrastructure for the collection of waste, sorting, and recycling of plastics in the country and unawareness regarding the recycling of plastics are likely to hinder the market growth.

On the basis of Material Type, the Polyethylene Terephthalate (PET) segment is anticipated to grow at a higher CAGR over the forecast period. The growing usage of PET in several sectors such as construction, packaging, and textile industries as they have lower cost is a major factor that is driving the growth of the segment in the market. The PET offers various remarkable advantages such as high stiffness & strength, lightweight, easy & effective transportation, excellent electrical insulating properties, and safe for contact with food & beverages as approved by FDA, which supporting the segment growth. In addition to this, several institutions and the government is focusing on developing various innovative recycling technologies. For example, in 2019, a team of researchers from King Abdullah University of Science and Technology (KAUST), Saudi Arabia, converted the recycled polyethylene terephthalate (PET) into porous membranes for purification & filtration applications within the chemical industry to separate the liquids from the molecules.

Key Developments:

- In 2019, Napco National in the 14th Gulf Petrochemicals and Chemicals Association (GPCA) Forum formed a strategic alliance with the petrochemical producers to highlight the importance of decreasing the negative impact on the environment of plastic waste in the petrochemical industry.

The Saudi Arabia Plastic Recycling market has been segmented based on the material type and application. Based on the Material Type, the market has been segmented into Polyethylene Terephthalate (PET), Polypropylene (PP), High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), Polystyrene (PS), Polyvinyl Chloride (PVC), ABS, Nylon, Polycarbonate, and Others. Based on the Application, the market has been segmented into Packaging, Building & Construction, Textile, Automotive, Industrial, Consumer Goods, Oil & Gas, Renewable, and Others.