Hybrid Additive Manufacturing Machines Market & Trends Analysis Report by Material, By End-Use Industry and By Region – Global Opportunities & Forecast, 2020-2027

Hybrid Additive Manufacturing Machines Market & Trends Analysis Report by Material (Titanium, Aluminum, Steel, Nickel, and Others), By End-Use Industry (Aerospace & Defense, Energy & Power, Electronics, Medical, Automotive, Other End-Use Industries) and By Region

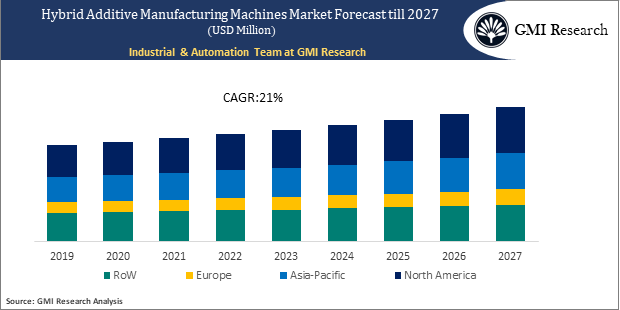

Hybrid Additive Manufacturing Machines Market was valued at USD 81 Million in 2019 and is expected to register a CAGR of 21% during the forecast period.

Introduction of the Hybrid Additive Manufacturing Machines Market Report

Hybrid additive manufacturing refers to the method or process of making objects from the strength of additive manufacturing, such as 3D objects. Hybrid manufacturing is a combination of subtractive manufacturing and additive manufacturing. These systems enable users to make and finish the part in a single setup by reducing errors as additive manufacturing part does not have to leave one machine to be reset on a second machine.

To have an edge over the competition by knowing the market dynamics and current trends of “Hybrid Additive Manufacturing Machines Market,” request for Sample Report here

Market Dynamic

Key Drivers and Emerging Trends

The major factors propelling the growth of the global hybrid additive manufacturing machines market are reduced cost of production, growing government funding, advancements in technologies and materials, and decreased complexity of manufacturing design. For instance, in 2017, Optomec, Inc. partnered with Tongtai Machine & Tool Company, one of the largest machine tool suppliers in Taiwan, to integrate the Optomec LENS Print Engine and add metal printing capability to its AMH-350 (Additive Manufacturing-Hybrid) vertical milling machine. Since the first technical advancement, i.e. vat polymerization, product designers and manufacturers have been able to swift the process of prototyping, design, and production immensely. Presently, a large number of advancements are made in additive manufacturing technology that provides a wide range of options for producers, designers, and manufacturers. For instance, Direct Energy Deposition (DED) is an additive manufacturing method, which could be used in hybrid solutions. This technology is considered an ideal option for repairing key components and producing large metal parts as it is capable of creating complex shapes. These factors are contributing to the growth of the global hybrid additive manufacturing machines market.

The adoption of hybrid additive manufacturing across multiple industries, such as in automotive and aerospace industries for its use in the manufacturing of highly complex parts is supplementing market growth. In the healthcare industry, hybrid additive manufacturing is used in patient-specific dental implants and prosthetics, which is a cost-effective solution. Furthermore, this technology is also beneficial in the field of repair and maintenance as it eliminates the need for manufacturing a new part from scratch and reduces the number of steps involved to repair a part. These factors play a vital role in augmenting the growth of the global hybrid additive manufacturing machines market.

Do you want to know more about the Research process and detailed Methodology, Request Research Methodology of this report

Material – Segment Analysis

Based on the material, the aluminum segment is expected to grow at a higher CAGR over the forecast period. The scientific and industrial sectors are likely to benefit from the manufacturing of lightweight and complex structures with enhanced functionality. Aluminum is a crucial material that helps in the weight reduction of several industrial components. Furthermore, the growing investments for the development of new alloys of metals are driving the growth of the segment in the global hybrid additive manufacturing machines market. For instance, Rusal, a Russian aluminum company, is investing in their research & development activities to develop 3D printing scandium-aluminum alloy for the shipbuilding industry.

End-Use Industry – Segment Analysis

On the basis of the end-use industry, the medical segment is anticipated to grow at a faster CAGR over the forecast period. In the medical sector, hybrid additive manufacturing is used in making various products, which includes prosthetics & implants, scaffolds, and surgical equipment. It is beneficial in the medical industry as it provides the option to customize parts rather than using pre-made titanium pieces. Furthermore, the growing incidences of surgeries supported by the rising adoption of the advancements in medical technology are significantly contributing to the growth of the medical segment in the global hybrid additive manufacturing machines market. For instance, in 2020, Mitsubishi Chemicals Advanced Materials Plastics (MCAM) partnered with Matsuura Machinery Corporation to invest in LUMEX-Avance 25 hybrid metal 3D printing machine, which combines 3D metal printing and finishing into one step.

In case, any of your pain points areas are not covered in the current scope of this report, Request for Free Customization here

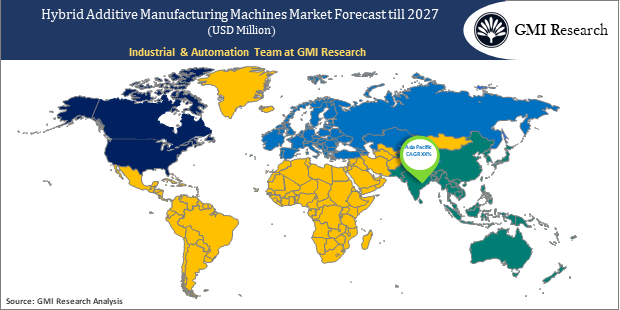

Region – Segment Analysis

Based on the region, the North America region is projected to dominate the market during the forecast period. North America has a higher consumption of hybrid manufacturing machines as compared to other regions. Furthermore, North America has been the early adopter of advanced medical technologies. The growing healthcare expenditure, low manufacturing cost, and increasing surgical procedures instead of medical tourism are the major factors boosting the growth of the market. In addition, the high adoption of hybrid manufacturing by automotive companies, such as General Motors, in the U.S. is surging the growth of the hybrid additive manufacturing machines market in North America.

Top Market Players

Various notable players operating in the market include 3D Systems, Inc., Melrose Industries PLC, ExOne GmbH, Arcam AB, ENVISIONTEC, INC., Materialise NV, CleanGreen3D Ltd., Optomec, Inc., voxeljet AG, and Mazak Corporation, among others.

Key Developments:

-

- In 2019, Mazak Corporation, partnered with Oak Ridge National Laboratory (ORNL), a manufacturing demonstration center. They signed a Cooperative Research and Development Agreement (CRADA). Under the agreement both firms worked under the sUS Department of Energy (DoE) to develop the use of Hot Wire Deposition (HWD) in additive manufacturing of parts.

- In 2018, 3D Systems, Inc., partnered with GF Machining Solutions to improve metal part production and to redefine the manufacturing environment for manufacturers. This partnership helped manufacturers in the efficient production of complex metal parts, within tight tolerances, and reduced the overall cost of operation.

Segments covered in the Report:

The global hybrid additive manufacturing machines market has been segmented on the basis of material, end-use industry, and regions. Based on material, the market is segmented into titanium, aluminum, steel, nickel, and others. Based on end-use industry, the market is segmented into aerospace & defense, energy & power, electronics, medical, automotive, and other end-use industries.

For detailed scope of the “Hybrid Additive Manufacturing Machines Market” report request a Sample Copy of the report

Key questions answered in this research report:

-

- At what pace is global hybrid additive manufacturing machines market growing? What will be the growth trend in the future?

- What are the key drivers and restraints in hybrid additive manufacturing machines market? What will be the impact of drivers and restraints in the future?

- What are the regional revenues and forecast breakdowns? Which are the major regional revenue pockets for growth in the global hybrid additive manufacturing machines market?

- Which material generated maximum revenues in 2019 and identify the most promising material during the forecast period?

- What are the various end-use industry areas of global hybrid additive manufacturing machines market and how they are poised to grow?

- What companies are the major participants in this market and their business strategies, how does the competitive landscape look like?

|

Report Coverage |

Details |

| Market Base Year |

2019 |

| Market Forecast Period |

2020-2027 |

| Market Revenues (2019) |

USD 81 Million |

| Base Year & Forecast Units |

Revenues (USD Million) |

| Market Segment | By Material, By End-Use Industry, By Region |

| Regional Coverage | Asia Pacific, Europe, North America, and RoW |

| Companies Profiled | 3D Systems, Inc., Melrose Industries PLC, ExOne GmbH, Arcam AB, ENVISIONTEC, INC., Materialise NV, CleanGreen3D Ltd., Optomec, Inc., voxeljet AG, Mazak Corporation, among others; a total of 10 companies covered. |

| 25% Free Customization Available | We will customize this report up to 25% as a free customization to address our client’s specific requirements |

Market Segmentation

Global Hybrid Additive Manufacturing Machines Market by Material

-

- Titanium

- Aluminum

- Steel

- Nickel

- Others

Global Hybrid Additive Manufacturing Machines Market by End-Use Industry

-

- Aerospace & Defense

- Energy & Power

- Electronics

- Medical

- Automotive

- Other End-Use Industries

Global Hybrid Additive Manufacturing Machines Market by Region

-

- North America Hybrid Additive Manufacturing Machines Market (Option 1: As a part of the free 25% customization)

- North America Hybrid Additive Manufacturing Machines Market by Material

- North America Hybrid Additive Manufacturing Machines Market by End-Use Industry

- US Hybrid Additive Manufacturing Machines Market All-Up

- Canada Hybrid Additive Manufacturing Machines Market All-Up

- Europe Hybrid Additive Manufacturing Machines Market (Option 2: As a part of the free 25% customization)

- Europe Hybrid Additive Manufacturing Machines Market by Material

- Europe Hybrid Additive Manufacturing Machines Market by End-Use Industry

- UK Hybrid Additive Manufacturing Machines Market All-Up

- Germany Hybrid Additive Manufacturing Machines Market All-Up

- France Hybrid Additive Manufacturing Machines Market All-Up

- Spain Hybrid Additive Manufacturing Machines Market All-Up

- Rest of Europe Hybrid Additive Manufacturing Machines Market All-Up

- Asia-Pacific Hybrid Additive Manufacturing Machines Market (Option 3: As a part of the free 25% customization)

- Asia-Pacific Hybrid Additive Manufacturing Machines Market by Material

- Asia-Pacific Hybrid Additive Manufacturing Machines Market by End-Use Industry

- China Hybrid Additive Manufacturing Machines Market All-Up

- India Hybrid Additive Manufacturing Machines Market All-Up

- Japan Hybrid Additive Manufacturing Machines Market All-Up

- Rest of APAC Hybrid Additive Manufacturing Machines Market All-Up

- RoW Hybrid Additive Manufacturing Machines Market (Option 4: As a part of the free 25% customization)

- RoW Hybrid Additive Manufacturing Machines Market by Material

- RoW Hybrid Additive Manufacturing Machines Market by End-Use Industry

- Brazil Hybrid Additive Manufacturing Machines Market All-Up

- South Africa Hybrid Additive Manufacturing Machines Market All-Up

- Saudi Arabia Hybrid Additive Manufacturing Machines Market All-Up

- UAE Hybrid Additive Manufacturing Machines Market All-Up

- Rest of world (remaining countries of the LAMEA region) Hybrid Additive Manufacturing Machines Market All-Up

- North America Hybrid Additive Manufacturing Machines Market (Option 1: As a part of the free 25% customization)

Major Players Operating in the Hybrid Additive Manufacturing Machines (Option 5: As a part of the Free 25% Customization – Profiles of 5 Additional Companies of your Choice)

-

- 3D Systems, Inc.

- Melrose Industries PLC

- ExOne GmbH

- Arcam AB

- ENVISIONTEC, INC.

- Materialise NV

- CleanGreen3D Ltd.

- Optomec, Inc.

- voxeljet AG

- Mazak Corporation

Frequently Asked Question About This Report

Hybrid Additive Manufacturing Machines Market [UP676A-00-0620]

The several end-use industries include aerospace & defense, energy & power, electronics, medical, automotive, and other end-use industries.

The various notable players operating in the market include 3D Systems, Inc., Melrose Industries PLC, ExOne GmbH, Arcam AB, ENVISIONTEC, INC., Materialise NV, CleanGreen3D Ltd., Optomec, Inc., voxeljet AG, and Mazak Corporation, among others.

The key factors propelling the growth of the hybrid additive manufacturing machines market are reduced cost of production, growing government funding, advancements in technologies and materials, and decreased complexity of manufacturing design.

The growth rate of Hybrid Additive Manufacturing Machines Market during forecast period is 21%.

- Published Date: Mar - 2021

- Report Format: Excel/PPT

- Report Code: UP676A-00-0620

Licensing Options

Single-User License:

The report is used by the purchaser (One Individual) only

Multi-User License:Report is shared with maximum 5 users (employees) including the purchaser of the purchasing corporation only

Corporate License:

Report is shared with unlimited user (employees) of the purchasing corporation only

The report is used by the purchaser (One Individual) only

Multi-User License:Report is shared with maximum 5 users (employees) including the purchaser of the purchasing corporation only

Corporate License:

Report is shared with unlimited user (employees) of the purchasing corporation only

Hybrid Additive Manufacturing Machines Market & Trends Analysis Report by Material, By End-Use Industry and By Region – Global Opportunities & Forecast, 2020-2027

$ 4,499.00 – $ 6,649.00

Why GMI Research